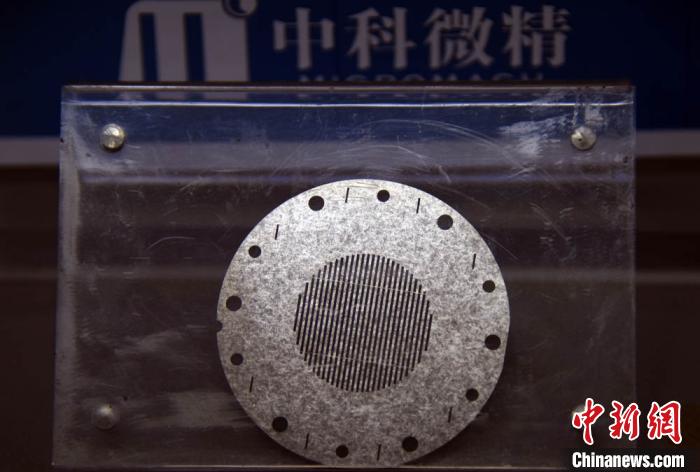

**Xi'an, November 7 (Reporter Sun Zifa)** —— A grating fine-cutting product developed by Zhongke Weijing. Photo by Sun Zifa.

Photonics manufacturing technology, which uses laser as a "knife" to "carve" specific materials according to needs, is known as a leading and revolutionary technology in the future advanced manufacturing field and has attracted much attention in China.

According to the latest news from the Xi'an Institute of Optics and Precision Mechanics of the Chinese Academy of Sciences (CAS XOMP), the institute has achieved a breakthrough from 0 to 1 in photonics manufacturing technology and equipment by focusing on the major strategic needs of the country and conducting continuous scientific research over the years.

**Xie Xiaoping, Deputy Director of the Xi'an Institute of Optics and Precision Mechanics of the Chinese Academy of Sciences, briefed the media on the progress of the institute's scientific and technological achievements in technology transfer and transformation.** Photo by Sun Zifa.

Meanwhile, relying on the CAS Technology Transfer and Transformation Key Special Project "Hongguang Special Project" and the CAS Technology Service Network Program, the Xi'an Institute of Optics and Precision Mechanics of the Chinese Academy of Sciences has promoted the organic combination of scientific research and industry. By integrating "talent + technology + finance + market" in a four-in-one development model, the institute has accelerated the industrialization process of photonics manufacturing.

Researchers from the Photonics Manufacturing Center of the Xi'an Institute of Optics and Precision Mechanics of the Chinese Academy of Sciences introduced that due to its extremely short duration of action (one thousand trillionths to one trillionth of a second), photonics manufacturing technology theoretically generates no heat during processing and is thus referred to as "cold processing." It also has extremely high peak power, which can solve processing bottlenecks that traditional methods cannot achieve, such as ultra-fine, damage-free, and material-selective processing. This technology is an important supporting technology for strategic emerging industries such as large aircraft and new-generation information technology in the country and a key means to promote the transformation and upgrading of the manufacturing industry.

**Xie Xiaoping, Deputy Director of the Xi'an Institute of Optics and Precision Mechanics of the Chinese Academy of Sciences, briefed the media on the progress of the institute's scientific and technological achievements in technology transfer and transformation.** Photo by Sun Zifa.

Meanwhile, relying on the CAS Technology Transfer and Transformation Key Special Project "Hongguang Special Project" and the CAS Technology Service Network Program, the Xi'an Institute of Optics and Precision Mechanics of the Chinese Academy of Sciences has promoted the organic combination of scientific research and industry. By integrating "talent + technology + finance + market" in a four-in-one development model, the institute has accelerated the industrialization process of photonics manufacturing.

Researchers from the Photonics Manufacturing Center of the Xi'an Institute of Optics and Precision Mechanics of the Chinese Academy of Sciences introduced that due to its extremely short duration of action (one thousand trillionths to one trillionth of a second), photonics manufacturing technology theoretically generates no heat during processing and is thus referred to as "cold processing." It also has extremely high peak power, which can solve processing bottlenecks that traditional methods cannot achieve, such as ultra-fine, damage-free, and material-selective processing. This technology is an important supporting technology for strategic emerging industries such as large aircraft and new-generation information technology in the country and a key means to promote the transformation and upgrading of the manufacturing industry.

**A corner of the equipment manufacturing and testing workshop of Zhongke Weijing.** Photo by Sun Zifa.

In addition, Zhongke Weijing has also relied on the Songshan Lake Materials Laboratory to build China's first demonstration line for the photonic automated processing of turbine blade cooling holes, realizing intelligent femtosecond laser extreme manufacturing. This provides comprehensive solutions for the ultra-fine cold processing of complex components in the fields of aviation, aerospace, and electronics.

Yang Xiaojun, chairman and general manager of Zhongke Weijing, said that in the Hongguang Special Project, the Xi'an Institute of Optics and Precision Mechanics of the Chinese Academy of Sciences focused on breaking through engineering technology, while Zhongke Weijing concentrated on the development and production of femtosecond laser high-end equipment. It has now become one of the pioneers of China's high-end photonic manufacturing equipment, achieving nearly 100% revenue growth for five consecutive years and has launched plans for listing on the Science and Technology Innovation Board.

So far, the Xi'an Institute of Optics and Precision Mechanics of the Chinese Academy of Sciences has incubated six high-tech companies in the field of photonic manufacturing, with a strong development momentum. It has generated a direct economic benefit of more than 2 billion yuan and an indirect economic benefit of more than 10 billion yuan, and has preliminarily formed an upstream and downstream industrial chain.

Xie Xiaoping, deputy director of the Xi'an Institute of Optics and Precision Mechanics of the Chinese Academy of Sciences, said that the achievements of the institute's photonic manufacturing industry are due to the "Xiguang Model" formed in the continuous exploration and practice of promoting the transfer and transformation of scientific and technological achievements. The core content includes "‘demolishing walls and opening the institute’, innovating employment models," "the institute holds shares but does not control, incubating enterprises but not running them, making enterprises the main body of innovation," and "professional incubation, entrepreneurial ecology, building a full-chain incubation carrier of ‘co-working space + incubator + accelerator’," which maximizes the release of scientific researchers' innovation and entrepreneurship vitality and provides comprehensive support for scientific researchers to engage in the transfer and transformation of scientific and technological achievements.

Xie Xiaoping revealed that in the next stage, the Xi'an Institute of Optics and Precision Mechanics will set up the CAS Photonic Manufacturing Engineering Laboratory to become the "engine" for the incubation of the photonic manufacturing industry, fully bridge the gap between scientific research and industry, build an accelerator for the photonic hard-tech industry, and create new types of photonic manufacturing industry clusters such as high-end laser manufacturing and photonic chip packaging to serve major national strategic projects and the construction of the national economy.

Original link:http://www.chinanews.com/gn/2020/11-07/9332718.shtml

微信公众号

微信公众号

抖音

抖音

视频号

视频号