Spring is strong, and the wave of intellectual creation is resurgent!

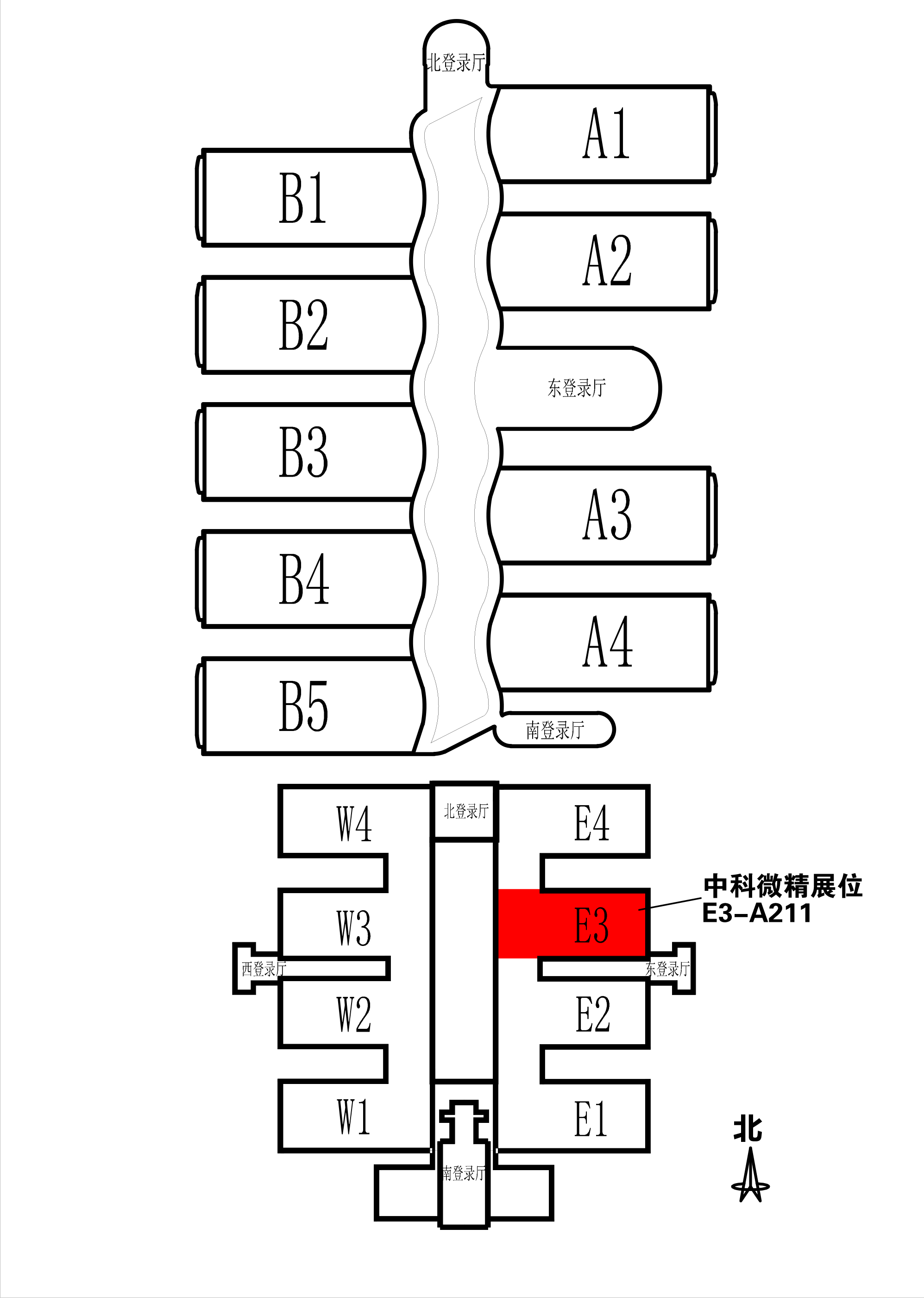

The 19th China International Machine Tool Show (CIMT2025) will be held on April 21-26, 2025 in China International Exhibition Center (Shunyi Pavilion), No.88 Yuxiang Road, Tianzhu District, Beijing. This exhibition is one of the four international machine tool exhibitions and the largest international machine tool exhibition in China. Committed to presenting you with an industry event of the most advanced new products, new technologies and new processes in the global machine tool industry.

Established in 2015, Xi 'an Micromach Technology Co., Ltd. focuses on the R&D, production and solution provision of high-end equipment for ultra-fast laser precision manufacturing, and belongs to the "Little Giant", a national-level special focus. Supported by the national key R&D plan of the Ministry of Science and Technology and the special project of high-grade CNC machine tools of the Ministry of Industry and Information Technology, the enterprise has overcome the core technologies such as ultra-short laser generation technology, laser micro-machining technology and liquid crystal spatial light modulation technology, and has taken the lead in developing ultra-fast laser precision manufacturing equipment with three to seven axes in China, thus solving the special processing technology problems such as precise drilling/fine cutting/high precision etching of complex microstructures in aviation, aerospace, electronics and other fields. We sincerely invite you to come to booth A211, Hall E3, China International Exhibition Center (Shunyi Pavilion).

Booth information

Micromach sincerely invites you to step into this photon intelligence field full of infinite possibilities!

Our booth information: Room A211, Hall E3

Micro Drilling Equipment (Double-Station)

Equipment introduction

The equipment takes a 10-axis double-station cast iron motion platform as the main body, adopts a parallel laser generation system as the light source, and outputs two independently controllable femtosecond laser beams based on the technology of femtosecond laser dynamic beam splitting and beam modulation. Combined with the multifunctional beam scanning module with independent intellectual property rights, the precision microstructure parallel asynchronous machining is carried out for different types of curved parts, including straight round holes or special-shaped holes such as round holes, inverted cone holes and dustpan holes.

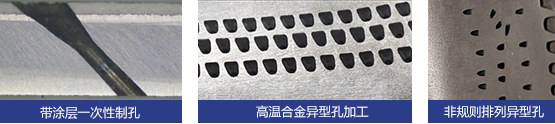

Processing case

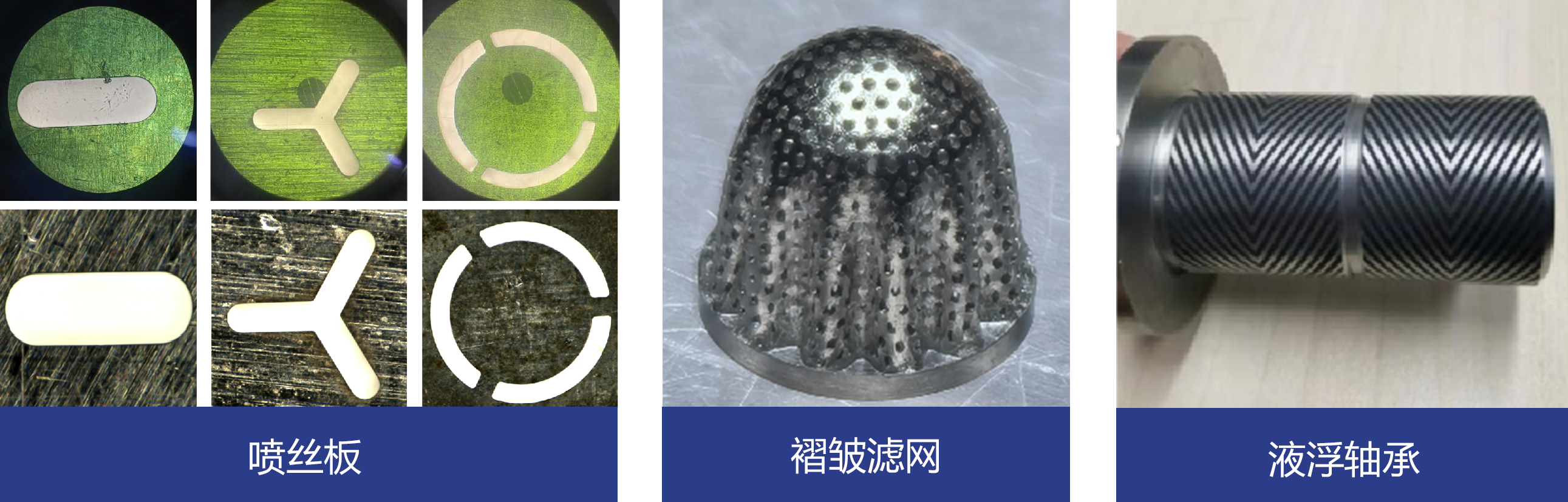

Ultra-Precision Drilling Equipment

Equipment introduction

UD series products are located in the field of micron-scale ultra-precision structure processing. The product adopts modular design concept to adapt to various application scenarios. Through different configurations and combinations, laser precise micro-hole, etching, cutting and turning can be realized. The precision drilling version is suitable for the precision machining of spinneret, dispensing nozzle, valve sleeve and filter screen, and the precision etching version is suitable for the precision machining of light guide plate mold, liquid floating bearing and wafer chuck.

Processing case

Cooling Hole Measurement Equipment

Equipment introduction

Panther-Eye M1000 is a special inspection equipment for aero-engine gas film holes, which adopts the industry-leading white light interference measurement technology to achieve high-precision measurement of gas film holes in various processing methods.

The measurement contents include: the aperture, position, angle and permeability detection of round holes and irregular holes, which can be applied to the quality evaluation of gas film holes after processing, and at the same time support the access of automatic production lines to realize full-automatic intelligent detection of gas film holes. The current version has supported the measurement of aperture, position and angle of gas film holes, and the measurement of pass parameters and profile parameters of special-shaped holes, which is simple and efficient to operate and is the first choice equipment in the field of gas film hole detection.

Inspection case

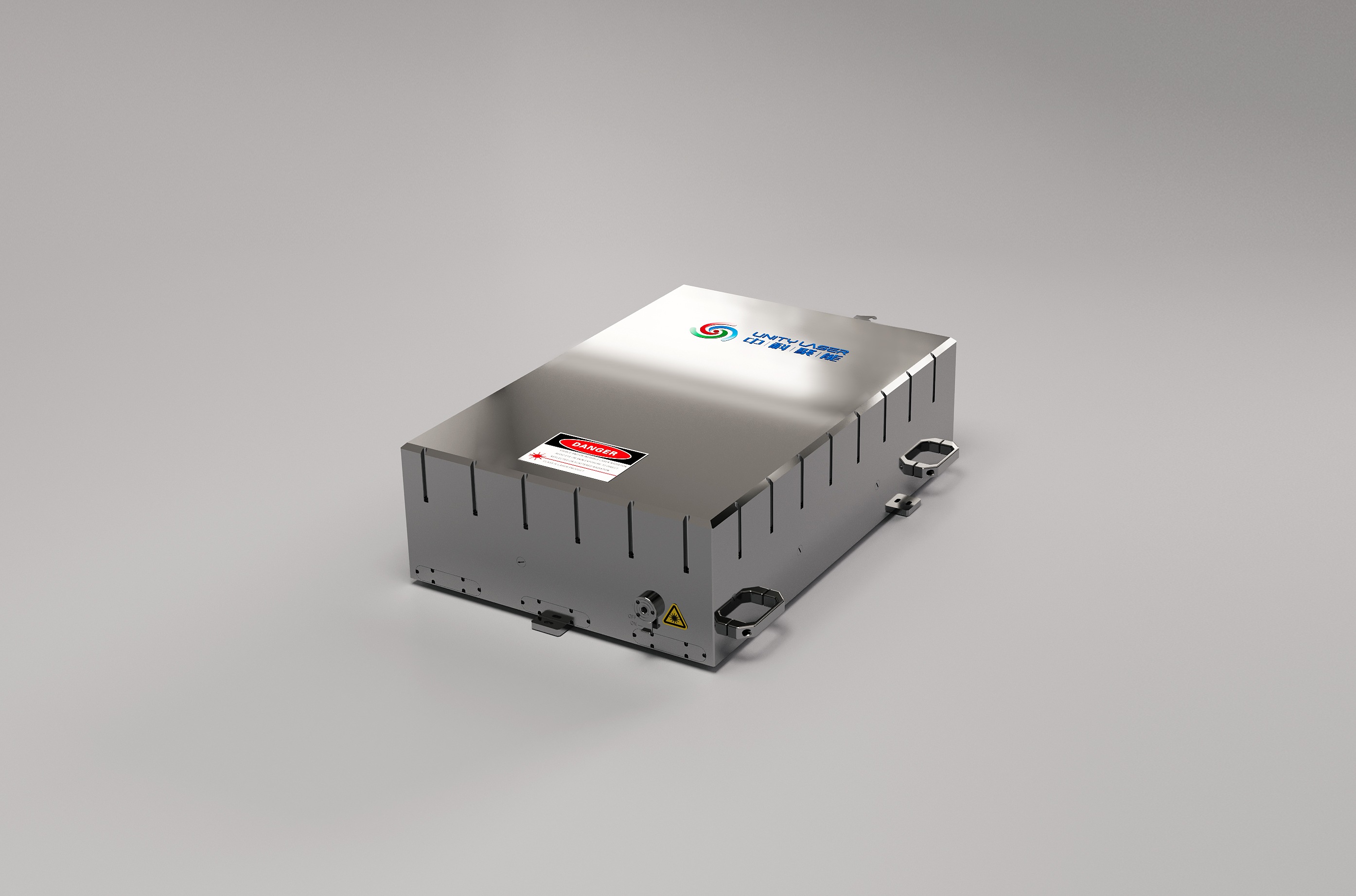

High power and high energy ultrafast laser

Equipment introduction

Facing the field of extreme manufacturing and micromachining, we have successfully launched a series of ultra-fast (picosecond, femtosecond) laser products with high power and high energy. The maximum output power can reach 200W, the maximum single pulse energy can reach 2mJ, and the peak power density can reach the petawatt level, which supports infrared, green and ultraviolet three-band output. Industrial standard product design, stable and reliable operation, and provide integrated expansion interface, interactive interface operation is simple. Ultrafast laser materials have strong adaptability and can be used for high-quality and high-precision machining of various materials such as high-precision drilling, cutting and etching.

Exhibition layout plan

traffic information

invitation letter

微信公众号

微信公众号

抖音

抖音

视频号

视频号