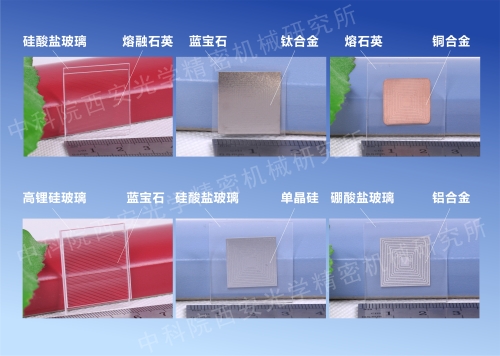

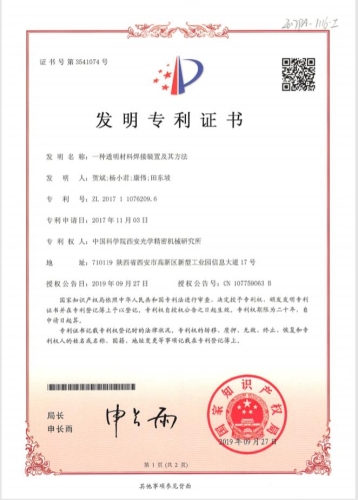

Recently, the team led by Associate Researcher He Bin from the Photonics Manufacturing Center of the Xi'an Institute of Optics and Precision Mechanics has made a breakthrough in the micro-welding of glass materials with heterogeneous materials such as metal alloys and single-crystal silicon using ultrafast lasers. The team has successfully achieved high-strength direct welding of various types of glass (silicate glass, sapphire glass, quartz glass) with single-crystal silicon and alloys (copper, aluminum, titanium) through ultrafast laser micro-welding technology. The aerospace and aviation critical components samples that have been completed have passed performance tests, and the technology maturity has reached the level for engineering application. Since the reporting of related technologies by PolaOnyx in the United States and Heriot-Watt University in the United Kingdom in early 2019, this represents a technological breakthrough by Chinese research institutions in this field. The technology has now reached an internationally advanced level and has been granted a national invention patent (Patent No.: ZL 201711076209.6).

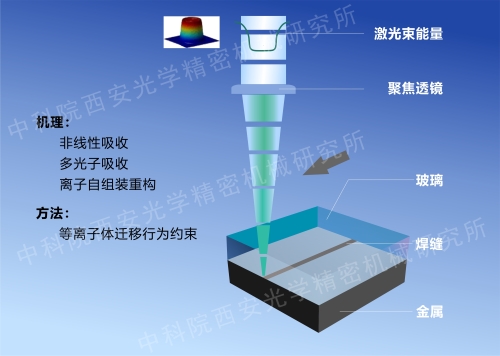

The ultrafast laser glass micro-welding technology is based on the nonlinear absorption mechanism of ultrafast laser energy, which allows for the plasma formation and subsequent recombination of different materials at the interface on a microscale to achieve precise welding. Tests have shown that the shear strength of welded samples of various types of glass with copper, titanium, and single-crystal silicon can reach 14.5–30.2 MPa. After 100 cycles of high and low-temperature tests ranging from -55°C to 120°C, the mechanical properties of the welds remain unchanged. The gas tightness of the welds can reach (2.8–5) × 10^-9 Pa·m^3/s in helium leak tests, and all performance indicators meet the relevant standards. The team has already started medium and small batch processing trials for related components and has established cooperation mechanisms with domestic aerospace and aviation institutes to promote the industrialization of this technology.

Since 2017, Associate Researcher He Bin has been collaborating with the micro-welding team of the Fraunhofer Institute for Laser Technology (Fraunhofer ILT) in Germany. In late 2018, he first proposed the ultrafast laser glass micro-welding technology based on the constraint of plasma migration behavior, solving the long-standing bottleneck issue that the surface quality requirements for pre-welded components were too high to meet engineering needs. During his time at the Xi'an Institute of Optics and Precision Mechanics, he has conducted research and established relevant research groups in laser micro-welding and fine 3D printing technologies.

Schematic diagram of ultrafast laser micro-welding of glass materials

Sample image of ultrafast laser micro-welding of glass materials

Patent certificate for the invention "A laser micro-welding device and method for transparent materials"

微信公众号

微信公众号

抖音

抖音

视频号

视频号