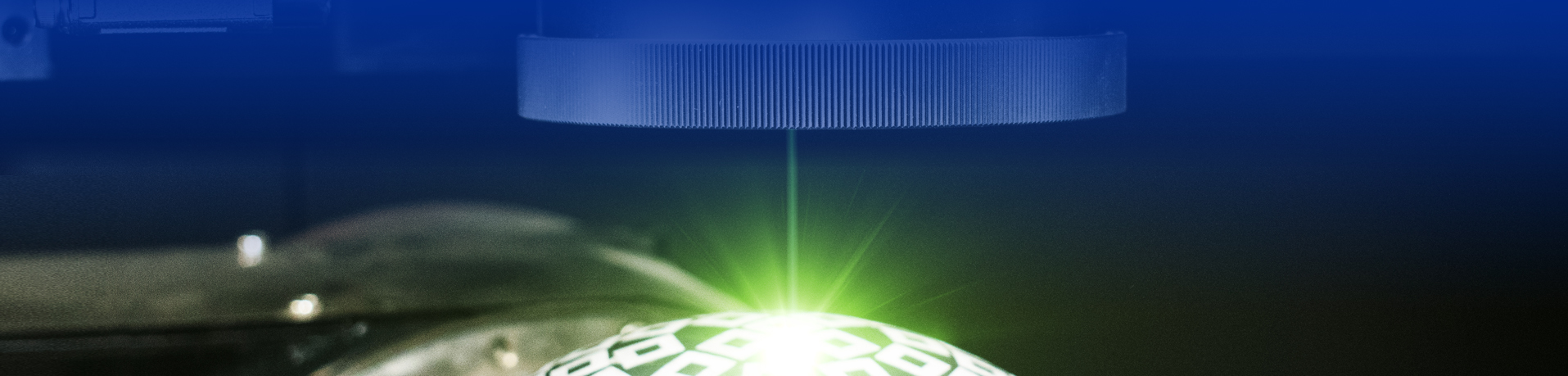

No burrs and no carbonization after cutting

No burrs and no carbonization after cutting

No burrs and no carbonization after cutting

No burrs and no carbonization after cutting

Gy laser processing line width≤0.02mm

Depth of processing≤0.01mm

Distance between lines0.2±0.005mm

Distance between lines0.2±0.005mm

Distance between lines0.2±0.005mm

black