Zhongke Micro precision has long been committed to the industrialization of high-end laser equipment, based on the improvement of accuracy and stability, and is moving toward intelligent machine tools. Founded in March 2015, the company focuses on the research and development/production of ultrafast laser precision hole making/etching/cutting equipment and the provision of solutions, and is the first national specialized small giant enterprise to realize the batch application of ultrafast laser manufacturing equipment in the aerospace field. The company led/participated in more than 10 major projects such as the national key research and development program and the 04 special project, and took the lead in developing three-axis to seven-axis ultrafast laser high-end manufacturing equipment, filling the domestic gap, breaking the foreign embargo, and generally reaching the international advanced level, and providing hundreds of key equipment and complete sets of solutions urgently needed by the country for aviation, aerospace, electronics and other fields. It has effectively supported the high-quality development of China's aero engine/gas turbine, satellite and other large country heavy instruments.

Focusing on ultrafine laser processing CNC machine tools, Wang Zi, president of the micro precision Innovation Research Institute, told Finance: "The production capacity of domestic low-grade CNC machine tools is relatively excess, the industry competition pressure is larger, everyone is fighting cost and efficiency; However, for high-grade CNC machine tools with high processing quality and precision, the overall gap in the country is shrinking, such as ultrafine laser micro-machining and other segments have achieved catch-up. Especially for CNC machine tools that are processed on complex surfaces." On the technical level, Zhongke Micro precision layout of machine tool compensation technology, environmental stability control technology and other adaptive technologies; At the management level, we have formed standardized specifications in the maintenance of machine tools to ensure the long-term stability of machine tools during use.

As machines that make machines, machine tools play an important role in manufacturing. Machine tools can process blanks or workpieces of metals and other materials to obtain the required geometric shape, dimensional accuracy and surface quality, also known as "industrial mother machines".

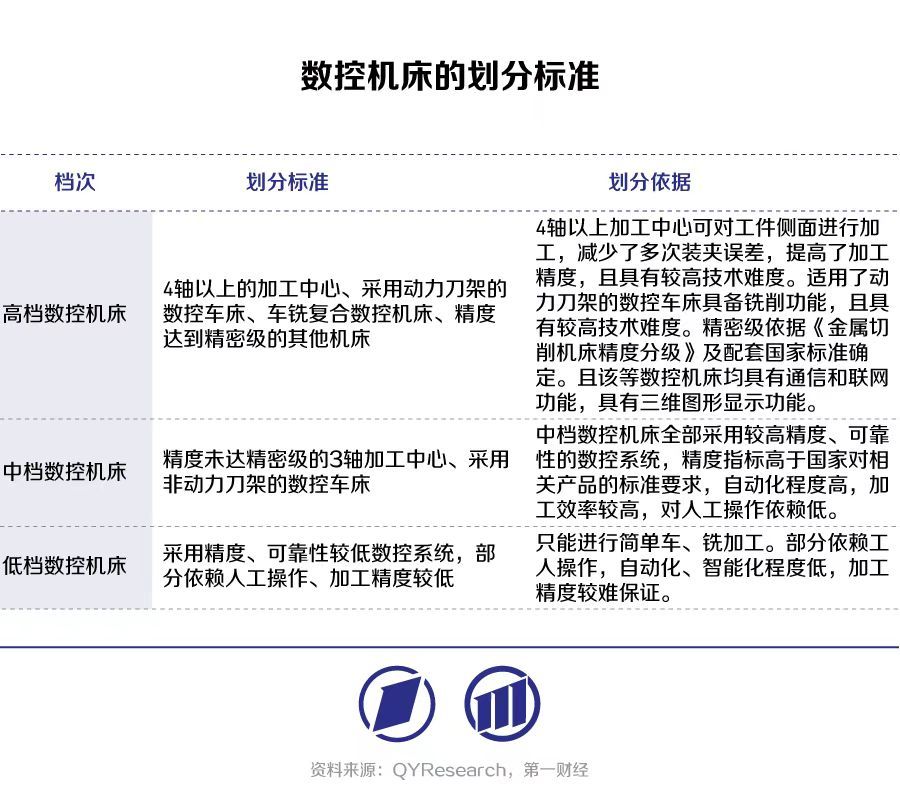

CNC machine tool is a machine tool that uses digital information to control the movement of the machine tool and its processing process. It is a modern mechatronics equipment with high efficiency, high precision, high flexibility and high automation.

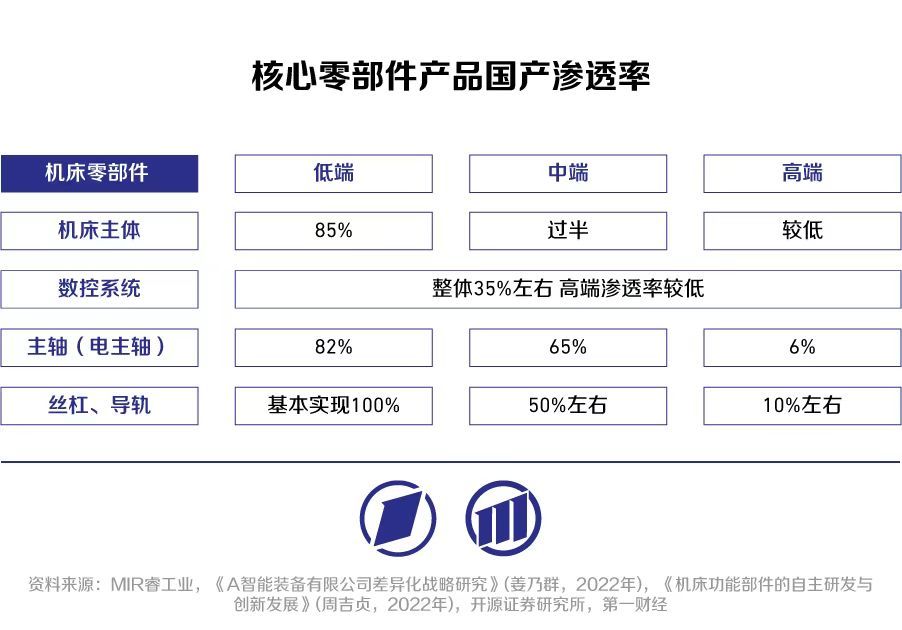

Overall, on the one hand, the CNC rate of China's machine tools still has a large room for improvement; On the other hand, at present, China's low-end CNC machine tools have basically reached self-sufficiency, and the mid-end CNC machine tools have basically achieved domestic substitution, but the localization rate of high-end CNC machine tools is still at a low level. Companies led by Kede Numerical Control (688305.SH), Huazhong Numerical Control (300161.SZ), Zhongke Micro Precision, Haitian Precision (688182.SH), Newey Numerical Control (688697.SH), Yuhuan Numerical Control (002903.SZ), etc., are constantly exploring the high-end machine tool market.

China is a large machine tool manufacturer and consumer, and the CNC rate needs to be improved

China is the world's largest machine tool manufacturer and consumer. According to the data of the German Machine Tool Manufacturers Association, the output value of China's machine tool in 2022 is about 181.8 billion yuan, accounting for 32.0% of the world; Machine tool consumption is about 183.92 billion yuan, accounting for 32.2% of the world; Machine tool output value, sales are the world.

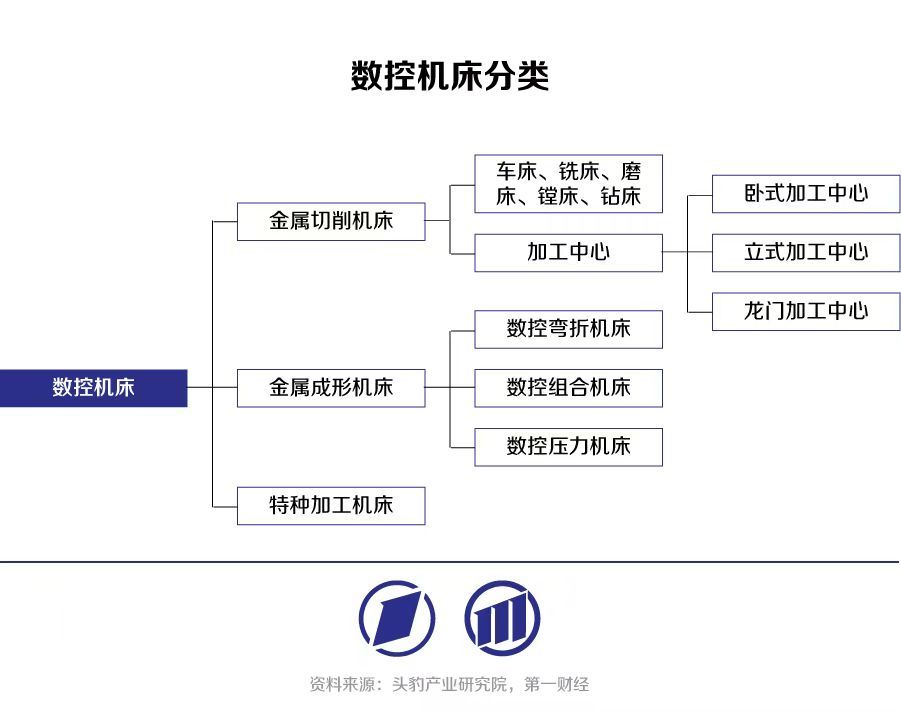

Machine tools mainly include metal cutting machine tools, metal forming machine tools and special processing machine tools.

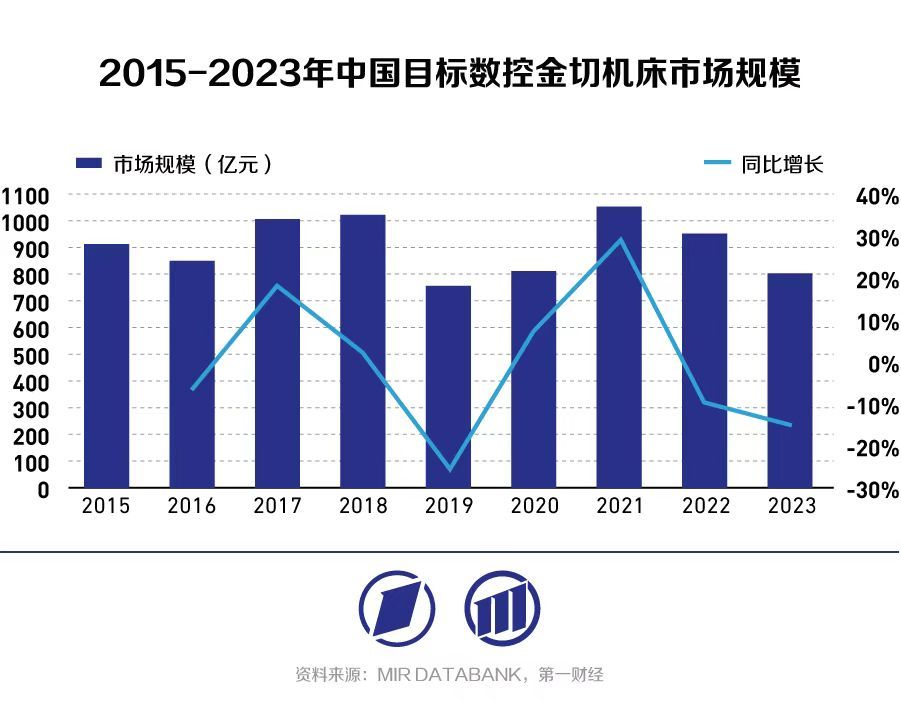

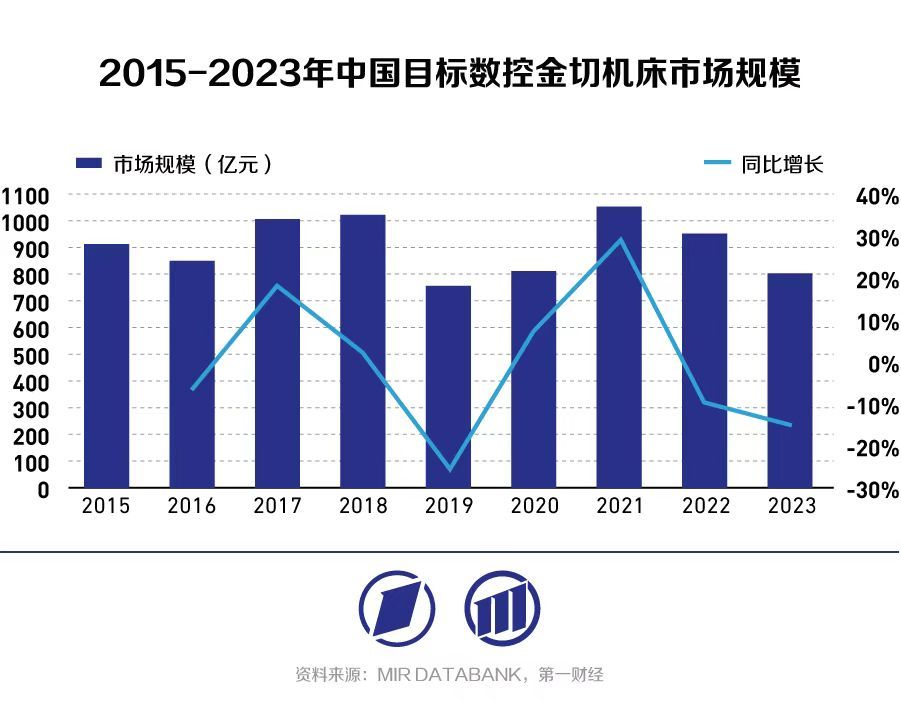

Taking metal cutting machine tools as an example (the National Bureau of Statistics only statistics metal cutting machine tools), according to MIR Rui industrial data, in recent years, China's metal cutting machine tools are 80 billion to 110 billion yuan, about 80.8 billion yuan in 2023. In 2023, China's exports of gold cutting machine tools reached 11.95 billion yuan, and the compound growth rate of nearly five years from 2019 to 2023 reached 30%, and it is expected that exports will reach 15 billion yuan in 2024, and the figure will continue to increase in 2025.

The cyclical change characteristics of metal cutting machine tools are extremely significant, usually manifested as a large cycle every 10 years, a small cycle of 3-4 years, 2023, 2024 is at the end of the large cycle replacement tide, the starting point of the fluctuation cycle. From the perspective of the service life of machine tools, MIR expects that the domestic market will enter a new upward cycle in the next decade. The compound growth rate in 2024-2028 is expected to reach about 2%.

Since 2020, the localization rate of China's machine tools has also been significantly improved, of which the growth rate in 2020 is fast, increasing by 4 percentage points compared with 2019. According to MIR Rui industrial data, as of 2023, the localization rate of China's machine tools has increased to 55%.

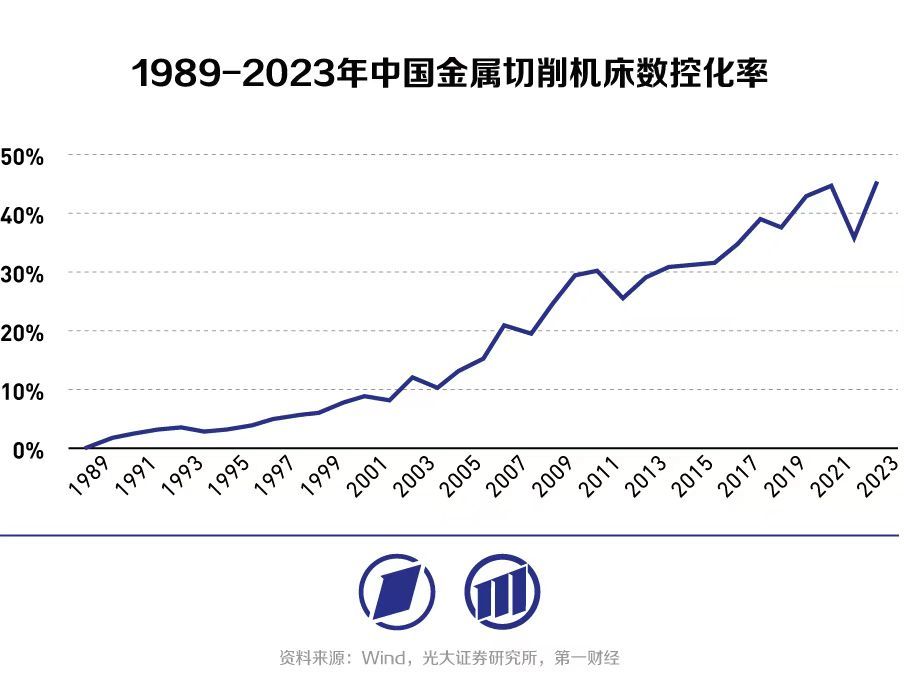

However, China's machine tool numerical control rate still has a large room for improvement. According to the data of the China Machine Tool Industry Association, the CNC rate of metal cutting machine tools in 2023 is 45.5%. The CNC rate of machine tools in Japan is maintained at more than 80%, and the CNC rate of machine tools in the United States and Germany is more than 70%.

The "Action Plan for Promoting large-scale equipment Renewal and replacing old consumer goods with new ones" issued by The State Council in early 2024 proposes to further promote the remanufacturing of traditional equipment such as machine tools, and by 2027, the penetration rate of digital R & D and design tools and the CNC rate of key processes of industrial enterprises above designated size will exceed 90% and 75% respectively.

Domestic high-grade CNC machine tool climbing Mican

CNC machine tools can be divided into low-grade, mid-grade and high-grade CNC machine tools, "domestic low-grade CNC machine tools of excess production capacity, industry competition pressure is larger, everyone is fighting cost and efficiency; However, for high-grade CNC machine tools with high processing quality and precision, the overall gap in the country is shrinking, such as ultrafine laser micro-machining and other segments have achieved catch-up." Wang Zi, president of Zhongke Micro Precision Innovation Research Institute, which focuses on ultrafine laser machining CNC machine tools, told Finance, "Especially CNC machine tools processed on complex surfaces."

According to the China Business Industry Research Institute data, China's high-end CNC machine tools in 2023 localization rate of about 6%.

China's CNC machine tool market can be roughly divided into three echelons: first, DMG, Yamazaki Mazak, Makino and other international machine tool enterprises represented by the majority of the high-end market share; The second is Jinan second machine tool, Shanghai Machine tool, Qinchuan Machine tool, Haitian Seiko, Newey Numerical control, Kede Numerical control, Yuhuan numerical control and other large state-owned enterprises and some private enterprises with core competitiveness, mainly occupy the middle market; Third, the low-end market is composed of many small and medium-sized enterprises.

It is reported that the current five-axis linkage technology represents the high-tech level of the machine tool field, and is an ideal machine for complex surface processing.

Compared with the traditional three-axis and four-axis CNC machine tools, the remarkable feature is multi-axis linkage, which can realize the simultaneous linkage of five axes, including X, Y, Z axes and two rotating axes. This multi-axis linkage structure enables five-axis CNC machine tools to be processed in more directions to achieve more complex processing tasks, and is the only means to solve the cutting and machining of key industrial products such as aerospace, aeroengine impels, blade discs, blades, and Marine propellers.

China's five-axis machine tools are mainly concentrated in aerospace, military, mold, automotive, shipbuilding and other industries, the current domestic demand continues to grow, MIR expects that in 2024, China's five-axis machining center market size will exceed 10 billion yuan, after 2028 or will move toward 20 billion yuan, entering a new round of growth stage, the market size will continue to grow in the next five years.

With the continuous improvement of technical capabilities of Beijing Jingdiao, Code Numerical Control, Shanghai Topu, Evermi and other enterprises, domestic manufacturers have gradually opened the five-axis market. Among them, Cord CNC five-axis CNC machine tools early into the aerospace field, in recent years to expand the civilian field, its investor exchange minutes show that in the domestic new orders, the civil field revenue accounted for about 30%-40%, the number accounted for more than 70%.

Improve accuracy and stability and move towards intelligent machine tools

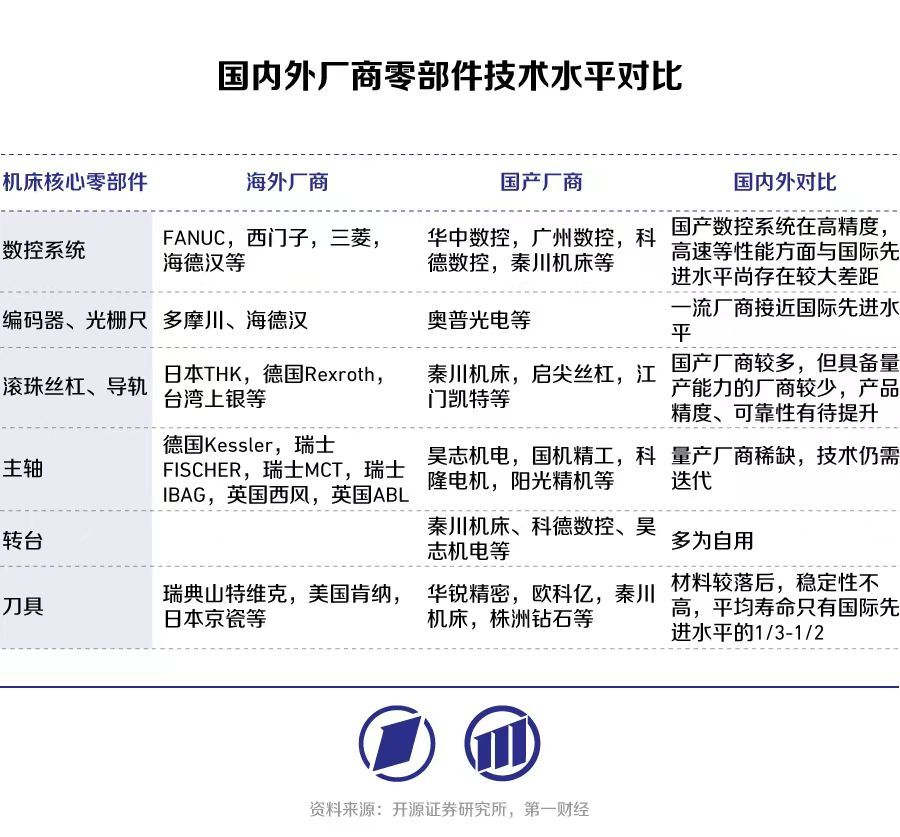

To achieve more breakthroughs in high-end CNC machine tools, improving accuracy is the key, and the accuracy and reliability of upstream core components have a greater impact on machine tool performance. The core parts of CNC machine tool mainly include CNC system, encoder, grating ruler, ball screw, spindle, guide rail, turntable and so on.

In terms of software, Open source securities believes that the main bottleneck in China is the error compensation ability of the CNC system, and the acceleration and deceleration control accuracy of the servo system can not meet the requirements of high-end CNC machine tools.

According to the main CNC system, as the "brain" of CNC machine tools, CNC system accounts for about 20% of the total cost of CNC machine tools. Huazhong 8 numerical control system is a domestic high-end numerical control system with five-axis linkage technology, which can compete with foreign high-end numerical control systems in key technical indicators such as multi-channel and multi-linkage.

It is reported that around 2017, the third party to the central CNC Central 8 high-performance CNC system test, a comprehensive standard of Germany, Japan and other countries of high-performance CNC system product functions, standard CNC system products more than 600 functional benchmarking degree reached 100%, high-grade CNC system products more than 1900 functional benchmarking degree of more than 98%.

In terms of hardware, Open source Securities said that the main bottleneck of domestic screw/guide rail, bearings, tools and other parts and fuselage materials thermal deformation, rigidity, stress, precision and other problems. Domestic Opu photoelectric (002338.SZ), Haozhi electromechanical (300503.SZ) and other manufacturers are making efforts to catch up. The "Key areas of technology roadmap" issued by the Ministry of Industry and Information Technology clearly defines the development goals of high-end CNC machine tools, in 2025, China's high-end CNC machine tools and basic manufacturing equipment, spindle, screw, line rail and other high-end functional components of the domestic market share will reach 80%.

"In fact, the more high-end, the lower the degree of universality of CNC machine tools. High-end CNC machine tools are often customized for a specific segment of the development of products, the need is not only the CNC machine itself, but some industry processing solutions. From this point of view, CNC systems and other parts, as well as our laser processing field involved in the light source laser, and even upstream CAD software, are the future of high-end CNC machine tools of the key technical power point and continuous research and development objects." Wang Zi expressed.

On the other hand, the development of high-end CNC machine tools in China also needs to improve stability.

"I think the accuracy of machine tools at home and abroad is not much different, the more important is the retention of our accuracy, the stability of the machine tool." In terms of stability, there is still a big gap between China and foreign countries." Wang Zi told Finance, "And the stability of the machine tool is a complex engineering problem, involving raw materials, design, assembly, maintenance, maintenance and other entire chain engineering technology."

In order to improve stability, Wang Zi said that at the technical level, Zhongke Micro Precision layout of machine tool compensation technology, environmental stability control technology and other adaptive technologies; At the management level, we have formed standardized specifications in the maintenance of machine tools to ensure the long-term stability of machine tools during use.

The relevant person said that the maturity and stability of the product are closely related to the testing and verification of the application. "The testing and verification of domestic CNC systems in various application scenarios is not sufficient. Software products themselves need continuous user feedback and iterative updates to achieve a spiral rise in product maturity and stability. We are also constantly optimizing this area. In the future, CNC machine tools will gradually transform to intelligent machine tools, and the intelligent level of CNC machine tools will continue to improve to reduce the threshold for the use of CNC machine tools."

Wang Zi has a similar view. "At present, many CNC machine tools and CNC systems require experienced craftsmen in large countries to operate well and process products with higher precision, and there are higher requirements for the ability of craftsmen." In the future, through the introduction of AI, the experience of engineers will become the ability of the equipment itself, and it will have the self-learning ability like people, and the production results of the machine tool will be fed back to the control system and the decision-making level, and the brain of the equipment will iterate through continuous learning to continue to improve the production capacity of the equipment."

According to the relevant people of Huazhong Numerical Control, Huazhong Numerical Control's type 9 numerical control system is the world's first intelligent numerical control system embedded with AI chip, integrating AI chip, integrating AI algorithm, gathering big data, integrating large model, integrating strong computing force, forming a real intelligent numerical control system platform, with large model-based numerical control system AI consultation and processing code generation functions. Achieve a major breakthrough in the global CNC system market.

"AI fault diagnosis is to learn the knowledge accumulated in the past to judge the possible causes of machine failure, to find out the problem point and give a solution." The current system is equivalent to the level of an engineer with two years of experience; Processing code generation can make programming more convenient, that is, tell the CNC system what kind of parts need to be processed, put forward processing requirements, the system will automatically generate a reference code and send it to the machine tool. With the continuous accumulation and learning of knowledge, the experience of numerical control system will be more and more rich, and the threshold of efficient use of numerical control machine tools will be lower and lower." Central China numerical control relevant person said.

However, as mentioned above, the improvement of product accuracy, maturity and stability can not be separated from the continuous verification process of the application side, the current CNC rate of China's machine tool still has a large room for rise, so the intelligent machine tool product distance from the real maturity, still need to go through continuous optimization and upgrading and iterative innovation.

(This article is from Finance and Economics)

微信公众号

微信公众号

抖音

抖音

视频号

视频号